1. Præcis temperaturkontrol, personlig komfortoplevelse

Den nyt energi elektronisk styret luftkølesystem , med sin avancerede elektroniske styringsteknologi, kan opnå subtil styring af indendørstemperaturen, langt ud over den enkelte temperaturindstillingstilstand for traditionelle klimaanlæg. Systemets indbyggede intelligente sensor kan overvåge indendørs temperatur, luftfugtighed, menneskelig aktivitet og andre parametre i realtid og automatisk justere til den temperatur, der passer bedst til det aktuelle miljø og den menneskelige opfattelse gennem kompleks algoritmeanalyse. Denne personlige temperaturstyringsstrategi undgår ikke kun ubehag forårsaget af for stor temperaturforskel, men forhindrer også effektivt sundhedsproblemer, der kan være forårsaget af at være i et fast temperaturmiljø i lang tid, såsom "klimaanlægssygdom". Derudover kan brugere også fjernstyre temperaturen derhjemme når som helst og hvor som helst via mobiltelefonens APP, og nyde den ultimative bekvemmelighed og komfort.

2. Høj effektivitet og energibesparelse, hvilket reducerer energiforbrugsomkostningerne

Den high efficiency and energy consumption characteristics of the new energy vehicle electronic control system and air cooling system provide a powerful reference for the application of new energy electronic temperature controlled air cooling system in the home field. The system adopts advanced frequency conversion technology and energy efficiency optimization algorithm, which can automatically adjust the operating speed of the compressor and fan according to the indoor load to avoid unnecessary energy waste. During the cooling or heating process, the system can accurately control the input and output of energy to ensure that every bit of energy can be fully utilized. This energy-efficient design not only reduces household energy expenses, but also reduces the impact on the environment, which is in line with modern families' pursuit of green and low-carbon life.

3. Tilpassede forme til at imødekomme forskellige behov

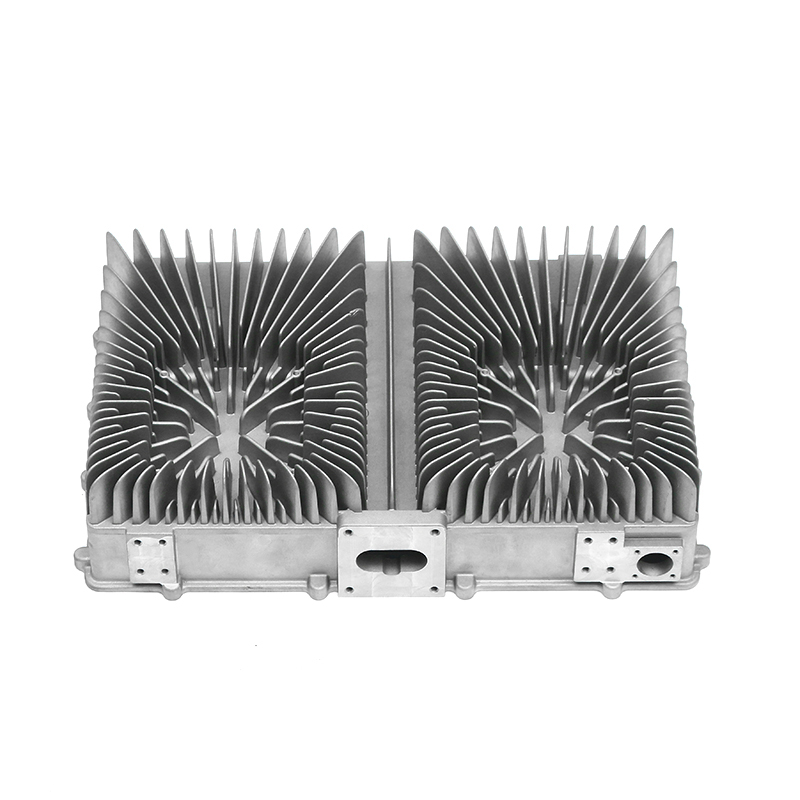

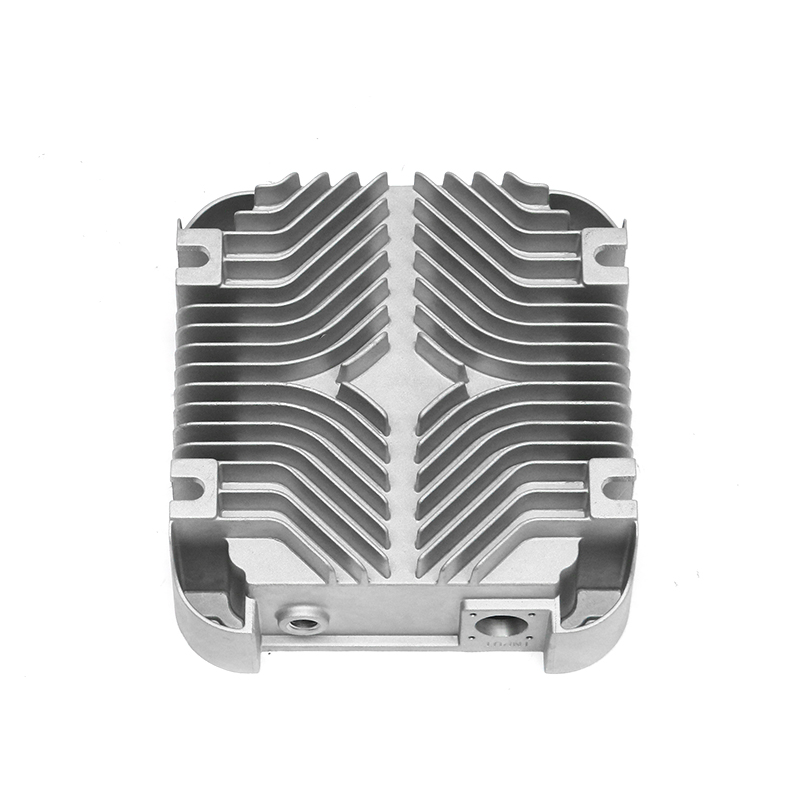

Den high customization requirements of the electric control air cooling system of new energy vehicles have promoted the continuous advancement of mold manufacturing technology. Similarly, the application of new energy electric control air cooling series molds in the home field also shows strong customization capabilities. Mold manufacturers can tailor suitable air cooling system molds according to the specific needs of customers and the actual conditions of the home environment. Whether it is wall-mounted, cabinet-type or embedded installation, whether it is simple style, retro style or modern technology-filled appearance design, it can be met. This highly customized service not only enhances the overall beauty and personalization of the home, but also ensures the perfect integration of the air cooling system and the home environment.

4. Præcisionsbehandling for at sikre stabil kvalitet

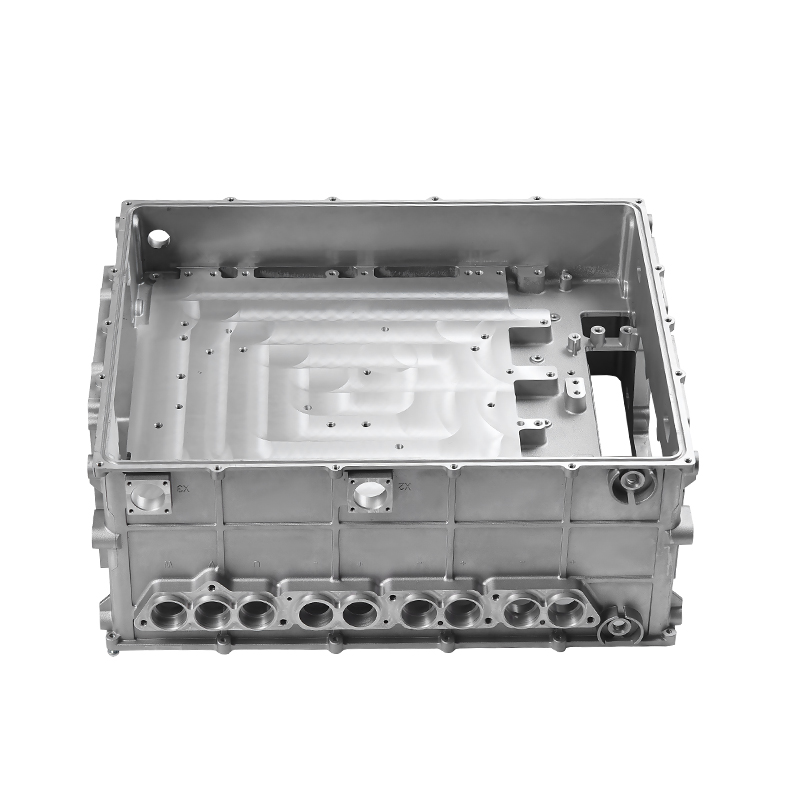

I design- og forarbejdningsprocessen af de nye forme i den nye energi-elektriske luftkølingsserie anvendes den mest avancerede CAD/CAM-teknologi og højpræcisionsbehandlingsudstyr. Anvendelsen af disse højteknologiske midler gør formfremstillingsprocessen mere præcis og effektiv. Gennem 3D-modellering og -simulering kan designere fuldføre det foreløbige design og optimeringsjustering af formen på computeren og undgå de fejl og defekter, der måtte være i traditionelt manuel design. Samtidig kan højpræcisionsbehandlingsudstyr sikre, at hver komponent i formen opnår ekstrem høj dimensionel nøjagtighed og overfladekvalitet, hvilket giver et solidt fundament for efterfølgende støbeprocesser såsom sprøjtestøbning eller trykstøbning. Anvendelsen af denne præcisionsbehandlingsteknologi forbedrer ikke kun formens kvalitetsstabilitet, men sikrer også, at luftkølesystemet kan opretholde fremragende ydeevne under brug.

5. Holdbar og stabil, forlænger levetiden

Den new energy electric control air cooling series molds have also made great efforts in material selection and process application. The mold manufacturer selected high-quality steel, alloy and other wear-resistant, high temperature resistant and corrosion-resistant materials as the main components of the mold. These materials not only have good mechanical properties and processing properties, but also can maintain stable physical and chemical properties during long-term use. In addition, advanced heat treatment, surface treatment and other process methods are also used in the mold processing process to further improve the hardness and wear resistance of the mold. The combined effect of these measures enables the new energy electric control air cooling series molds to resist the test of various harsh environments and complex working conditions during use, maintaining stable performance output and a long service life. This not only reduces the frequency and cost of mold replacement, but also provides users with a more reliable and durable air cooling system product.